Epoxy Flooring vs Polyurethane Flooring in the Philippines

What are the differences between Epoxy and Polyurethane?

- Molecular Structure

- Durability

- Versatility

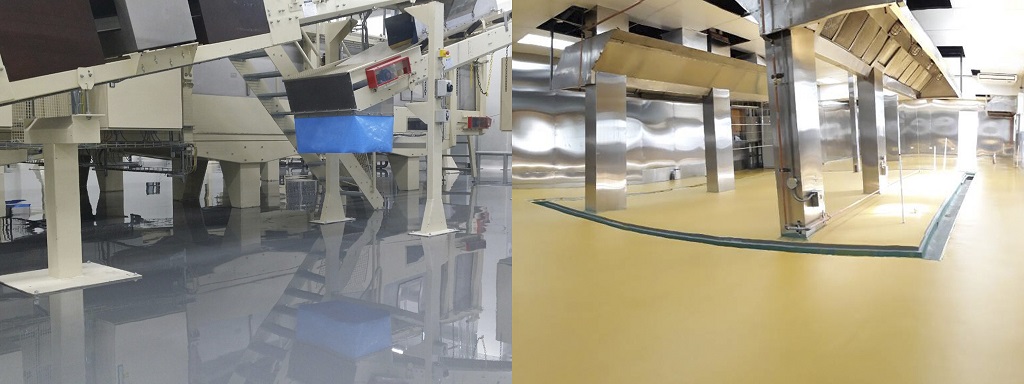

Resin floors in the Philippines are significant for industrial and commercial applications. The two main types of resin floors are Epoxy and Polyurethane. Both are different in their own way so it is important that industry professionals know about their particular qualities.

These floor coatings come in many formulas and additives to customize the components. The perfect flooring should be dependent on what it will be used for and the environment it will be settled in so whether you are choosing a polyurethane flooring or an epoxy coating in the Philippines, use this as your guide for these flooring solutions.

What is Epoxy?

To start off, let’s define Epoxy. It is a protective coating that is applied on top of existing cement or concrete substrates. It is a multi-component solution that requires proper and careful measurement and mixing of all parts. Coating the floors with epoxy helps protect the floor from mechanical abrasion. They are most common in facilities such as warehouses, logistic centers, dry process manufacturing plant and facilities with forklift traffic.

What is Polyurethane?

Polyurethane can protect a surface from corrosion and any degradation. It can have a gloss or matte finish. This type of flooring is combustion resistant. Unlike epoxy, resistance to UV light is higher and more stable. Additionally, it is resistant to scratches provided an additional coating is applied on top. Polyurethane is more flexible than epoxy. In areas where it is subject to wet conditions and extreme temperature swings, as well as attacks from chemicals and corrosive ingredients, they can benefit a lot from the flexibility of the polyurethane.

Molecular Structure

During the curing process of these resins, there are multiple types of components used which is the reason why the end result varies slightly. PUs have a higher density than epoxies which means that it is harder than the latter. Industrial professionals have long known that this type of flooring offers strength, durability, and resilience when and if they are faced with a variety of extreme conditions. These conditions include footfall, physical impacts, extreme temperatures, and corrosive chemicals.

Durability

PU systems are well-preferred by industrial facilities since it can withstand a myriad of challenges on a daily basis. You can even subject it to pressure by putting heavy equipment on top of it and it would survive these challenges. Organizations from different industries applaud the robust nature of Polyurethane flooring in the Philippines simply because it enhances industrial operations. In terms of structure, epoxies are rigid and it cannot handle intense heat well.

Versatility

Epoxy wins this round because it can easily adapt to different environments with ease. It is a much more suitable choice for decorative applications because you can get it in bright and glossy tones. Although PU can also be easy on the eye, Epoxy injects creativity into flooring installations which spell success for an interior design scheme.

Key Takeaway

Polyurethane flooring and epoxy flooring in the Philippines are popular choices for commercial and industrial facilities. Both are good types of resin flooring to choose from depending on the area in which it is used. Experts say that using both can effectively protect floorings. While epoxy can serve you the best in visuals and being rigid, Polyurethane will deliver on its promise of being a hard-wearing flooring both in wet and dry conditions.

Contact us to find out which is more suitable for you!