As much as you can survive without coating the flooring of your home, it’s something that you seriously have to consider if you want to truly make your home feel complete. In the Philippines, PU Flooring or Polyurethane Flooring is at the top of the most popular materials used to finish up floors. They bring about a different kind of texture and ambiance that it’s really a must-have for every industry.

That being said, polyurethane flooring, in particular, is interesting in itself. Often it’s called simply urethane which is completely different from what it is. In fact, it doesn’t contain any amount of the highly noxious chemical—rather it is composed of urethane polymers, chemical solvents and curing agents. These are usually used to protect surfaces of wooden furniture, and sometimes, even concrete flooring.

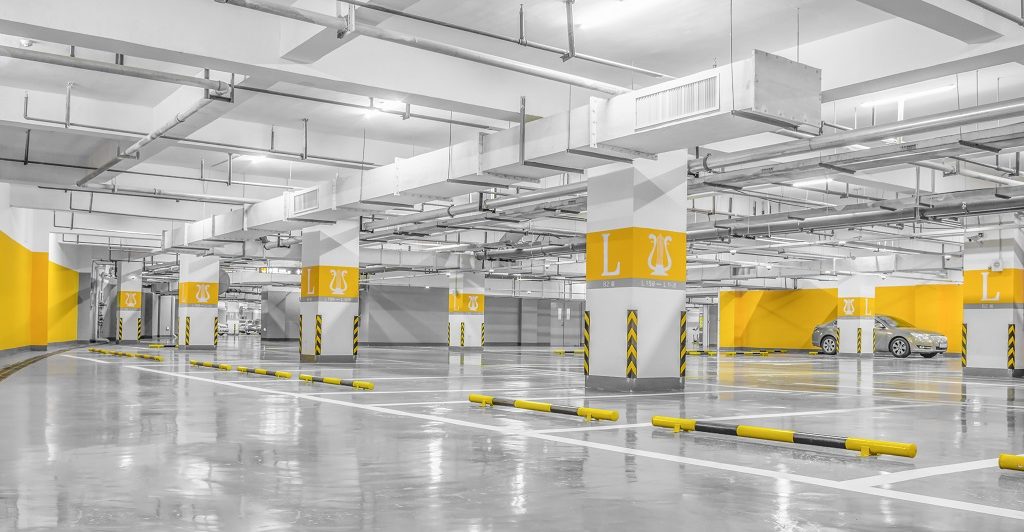

Polyurethane flooring in the Philippines has a lot of different applications. Whether it’s an industrial, residential, or commercial location, there will always be space for a polyurethane flooring application.

The Difference Between Polyurethane and Epoxy Flooring

These two materials are the most commonly used resins for finishing up floors. They are used in almost all applications—industrial, commercial, and even residential. This is because although different forms of flooring finishes, they are similarly durable, hard, and resistant to physical aberrations.

Other forms of similarities between them include their capability to provide waterproofing for the floor. But for the most part, they are used to providing extra protection to concrete floors from almost every kind of damage and dirt that might be a problem in the future.

That being said, these two types of flooring are more suited for different applications. Much of which is very specific. You have to take note of these factors whenever you’re choosing which one would be the best for a new establishment because it can have a significant effect on the functionality, as well as the comfort of people and even vehicles that will be using the floor.

Polyurethane flooring is known to be highly flexible and elastic. This gives them an edge when it comes to scratch resistance and other forms of physical damage. Because of this polyurethane flooring is often used in places where heavy traffic is expected.

Its elasticity is also very important for places where changes in temperature are likely to happen. When the temperature changes, the flooring would usually begin to expand or contract. Most flooring other than polyurethane would begin to crack once there’s a sudden change in the composition of the concrete below—but that’s not going to happen when you use polyurethane flooring.

A polyurethane coating can only be about 2 to 3 mils in thickness and can’t be adjusted. Any more or any less would lessen the quality of the flooring. Another point to talk about is that polyurethane flooring is UV stable. It won’t experience any kind of discoloration when exposed to some amount of sunlight over a period of time. This is perfect for some outdoor applications such as in car parks. Or general outdoor commercial spaces.

One of the defining features of polyurethane flooring is that it’s quite softer than epoxy. Meaning in some areas, it’s better to have this kind of flooring so that people can more comfortably step on the area. It is also offered in a variety of finishes, from satin to very glossy.

Although polyurethane flooring seems like it’s already a great product, keep in mind that epoxy flooring also has its own uniqueness to it. Epoxy flooring is typically available in three formulations: water-based, solvent-based. And 100% solid. These allow for a variety of thickness levels from 3 mils to 10 mils for a single coating. They also bond extremely well to properly prepared concrete. Sometimes, it can even be used as a resurfacing agent for old or worn out concrete that needs a new surface.

Epoxy flooring, particularly the 100% solid variant, is extremely hard, thick and impact resistant. The chemical composition, however, makes it relatively sensitive to U.V. light unless there are inhibitors included in the formula. Both polyurethane and epoxy flooring have a level of chemical resistance that depends largely on how they are formulated, but for the standard, they have relatively the same level of resistance.

Though this discussion is heavily favoring the polyurethane flooring, it’s important to keep in mind that both see use in different applications. Whether or not each of them should be used depends on the contractor, who would have the best knowledge of which one is the ideal material for flooring in a specific application.

Resin Types Used for Flooring Solutions

There are multiple types of resin used for different flooring solutions. In the Philippines, polyurethane flooring is one of the popular ones. However, it’s epoxy flooring that finds itself at the top of people’s priority lists. Take a look at our extensive list of flooring options for both industrial and commercial applications here!

Flowshield SL

This self-leveling epoxy floor coating system has a rather attractive and seamless glossy finish. It’s specifically designed for the automotive and aviation industry which needs high chemical and abrasion resistance.

Flowshield SL is chemical resistant, wear resistant, and easy to clean. It is also quite decorative as we offer them in various colors and finishes.

Flowshield CR

Another version of our self-smoothing epoxy flooring that boasts extremely high chemical resistance is the Flowshield CR. This is perfect for areas dedicated to dry processes that might experience a few chemical spillages.

The best applications for Flowshield CR include chemical storage areas, laboratories, warehouses, and printing plants.

Flowshield CR is USDA and FDA compliant, it has incredibly high chemical resistance and is capable of withstanding hard wear and tear. They are also known for being hygienic and easy to clean.

Flowshield Quartz

This can withstand many flooring problems. It has a high build and is relatively decorative. This self-leveling and pigmented epoxy flooring are suited to environments that experience a lot of traffic which in turn requires heavy cleaning regimes.

Flowshield Quartz is one of the more attractive options you can choose from. They have good chemical resistance and are hard-wearing. They’re also solvent-free and anti-microbial. Lastly, they are very decorative as they can be installed with numerous finishes and colors, and they also minimize visible scratches.

Flowshield ESD Conductive

This resin flooring is manufactured particularly for electrical applications. It is an anti-static coating that complies with a variety of electrical conductivity requirements.

It provides decent wear resistance, and is rather seamless and electrically safe. This coating is commonly used in dry processing locations that experience heavy foot and wheel traffic. Its electrical conductivity compliance lets it be used in laboratories, clean rooms, and equipment testing areas.

Flowshield SK

This epoxy flooring is highly resistant to chemicals, particularly SKYDROL hydraulic fluids. The coating is primarily used to help protect concrete in aircraft hangers. It strengthens the floor so that it’s able to deal with both the mechanical and chemical stress that comes with aircraft. They’re mostly used in places where aircraft are parked, worked on, or tested.

Flowshield SK is-hard wearing and solvent free. It boasts high resistance to jet fuel and is relatively easy to clean.

Peran SL

This is one of the lower maintenance resin floorings that still boasts decent wear resistance and high chemical resistance. It’s mostly used in locations that usually experience a lot of pedestrian traffic such as shops, department stores, restaurants, and basically different kinds of commercial areas.

Peran SL is chemical and wear-resistant. It’s also highly hygienic and quite attractive, making it very suitable for commercial applications.

Flowflake Marble

An epoxy flooring designed to be decorative through texture and vibrancy, the Flowflake Marble has large flakes scattered over a pigmented epoxy base for added design aesthetics.

It’s still finished with a clear sealer, making sure that the whole floor is attractive and practical.

This option provides you with an attractive flooring solution that has extensive design potential. It’s also hard-wearing and fairly easy to clean.

Flowflake Terrosso

Like the Flowfake Marble, this also contains a few flakes scattered over a pigmented epoxy base and finished with a clear sealer. This one, however, focuses more on being tougher and easier to clean.

Flowflake Kristalina

Another one that’s part of the Flowflake line, this too focuses on aesthetics. This resin flooring focuses on sparkling epoxy resin floor finishes which makes it ideal for modern contemporary environments.

This is mostly used for public places such as shops, malls, casinos and museums—most of which focus on minimalism.

Flowflake Kristalina is very aesthetically pleasing, hard-wearing and easy to clean.

Metallic Expressions

This is a type of epoxy flooring that is highly decorative and hard-wearing. It’s known for its advanced floor finish that results in a unique metallic finish that shows impact underfoot.

These Metallic Expressions are very attractive especially because of their interesting design. They’re also easy to clean and very durable.

Reasons Why You Should Implement Polyurethane Flooring

Based on the discussion above, polyurethane flooring is probably your best option for a high-quality durable floor. It has many benefits when used, and barely any kind of disadvantages to it. That said, there are still people that choose other forms of flooring instead of polyurethane. The reason being there are other, more suitable options than just polyurethane flooring.

in the Philippines, polyurethane flooring is probably one of the top options that every industry has when it comes to flooring because of its properties and characteristics. But why is it exactly an important decision? Here are a few reasons why polyurethane flooring is an obvious choice for your establishment:

You can expect heavy traffic in a certain area

Polyurethane flooring in the Philippines is usually used in places where there are heavy foot and vehicle traffic. Most of the time it is used in and around parking spaces and the path that leads to and from them. In fact, you can find whole multi-level parking spaces layered with polyurethane flooring right from where the parking starts. It’s strong enough to support heavy, consistent traffic with only very little maintenance if any. You can find locations such as events places in Manila utilizing polyurethane flooring because they always expect heavy traffic of cars and people all the time.

The same goes for foot traffic, though it’s not as harsh and heavy as vehicles, it’s more frequent. And here, the durability of the flooring isn’t the question, rather it’s for the comfort of the people that are stepping on it. Keep in mind that polyurethane flooring is softer than epoxy, even if it’s known to be much stronger, durable and flexible. By applying this kind of flooring you’re essentially making it easier for people to walk around in that area.

You need extra protection from the forces of nature

Polyurethane flooring is almost ideal for outdoor applications because of all its properties put together. it’s waterproof, extremely resistant to physical damages such as scratches and other forms of impact, and is immune to the effects of UV rays on it.

But the main factor as to why it’s perfect for these applications is its elasticity and flexibility regarding temperature. If you were to use other kinds of floor coating that doesn’t have the same amount of elasticity as polyurethane flooring in the Philippines, then most likely, a sudden, relevant change in temperature would cause parts of the floor to crack because of contractions or expansions of the concrete underneath.

Luckily, there’s not much volatility in the temperature in the Philippines regularly, however, during summer, the heat intensifies so much that it might cause problems through it all.

It isolates dust and dirt

This kind of flooring doesn’t let debris stick to it. Even most spills are very easy to clean up because even if it was left for a while, it won’t be sticking onto the coating.

This makes it very easy to clean and maintain. Whether you have a polyurethane coating for wooden floors or concrete, you’ll only need to do basic maintenance to keep things clean and tidy.

Cleaning these floors that are coated with polyurethane needs only a sweep and a mop to get things as clean as it is. The only thing that you have to take note of is the need for a mild cleanser for concrete flooring to keep it as clean as possible.

Other than that, there’s nothing too special with regards to how you clean this kind of flooring.

Types of Polyurethane Finishes

When you choose to get polyurethane or epoxy flooring in the Philippines, you also have to choose what kind of finish you want to have. Particularly for wood flooring, these will help add another level of texture to the decent aesthetic of wood flooring.

The most basic difference between the finishes is in the way light is reflected off of it. It doesn’t have any effect on the durability of the other—it’s more of a visual choice.

Satin Polyurethane

This is the most popular choice of a finish for hardwood flooring. This type of finish has a medium to low sheen or luster, making it able to hide dirt and scratches better than a gloss or high gloss polyurethane finish.

It’s considered to be the most balanced among the finish because it somehow possesses the best of both ends of the sheen spectrum.

Overall this finish is preferred by a lot of people because It’s easy to live with. it hides aberrations well, while still showing off the beauty of the floor. It’s also very easy to clean and maintain.

If you’re going for a more natural look on the floor this is the finish that you should use!

Semi-Gloss Polyurethane

A touch above the luster scale when compared to the satin polyurethane, this is usually as shiny as most people would prefer their flooring to be, particularly in their homes. It’s shinier and is primarily an oil-based polyurethane. Defining features of this finish include clarity and shine.

Be careful, however, because this kind of finish is not recommended for households with pets or very young children. This is largely because unlike satin polyurethane, these semi-gloss polyurethane finishes are vulnerable to scratches, dents, scuff marks and imperfections.

Gloss/High Gloss Polyurethane

This kind of finish has the highest luster level among all the other options. These are very seldom used for high traffic hardwood floors, rather it’s reserved for more exotic and unique hardwood species—particularly those that are truly a sight to behold. High gloss polyurethane sacrifices the ability to hide imperfections in order to more easily showcase the beauty of the hardwood floor.

This kind of finish isn’t recommended for a lot of situations. Especially when you have pets or children running around your house, you would much rather choose the satin polyurethane finish.

The High Gloss Polyurethane can be described as the one for artistic purposes. In terms of functionality, it is probably the worst option for you to use.

When it comes to choosing what kind of finish you’re going to get, the most important consideration is the level of sheen/luster that it has. For the typical family, satin polyurethane would be the best choice. It provides a balance between functionality and beauty all in one finish—it does, however, kind of make it hard to value the hardwood used in the flooring, however, it does make it look decent.

The other two gloss options are for older families or homes that have a rather mature set of people living there. This is because any kind of physical damage dealt with them will immediately be easy to see. These finishes are also needier for constant cleaning and maintenance, particularly high-gloss polyurethane.

The upside, however, is that they really emphasize the beauty of the hardwood that you choose. So if you are willing to prioritize your beauty and decoration over floor functionality, then you can choose these two finishes!

Let Flooring Solutions Answer All Your Flooring Questions

If you want your floor to be expertly coated and serviced with only the highest of quality polyurethane flooring in the Philippines, then your answers are all with Flooring Solutions. As one of the leading companies that deals with floor-related concerns, we are more than capable of answering all your flooring questions.

More often than not, you will be rewarded with flooring choices in the Philippines, be it Polyurethane flooring or epoxy flooring, there will be so many variations to choose from. Think carefully and choose the one that will best fit the place it’s going to be installed in.

Make your home feel complete with the most appropriate kind of flooring finish. Make it bloom exactly how you want it to be. For more information on how Flooring Solutions Philippines can help you, visit our website by clicking here!